Environmentally-friendly dimmable technology reduces energy consumption

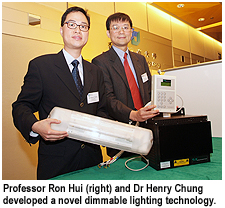

At a press conference on 18 April, Professor Ron Hui and Dr Henry Chung of CityU’s Department of Electronic Engineering demonstrated how the dimmable technology works in lamps and how it contributes to the reduction of environmental pollution. Both Professor Hui and Dr Chung pointed out that, in lighting systems, having dimming ability does not necessarily mean energy-saving, and energy-saving technology does not necessarily mean that it is environmentally-friendly. However, CityU’s novel dimmable lighting technology is both energy-saving and environmentally-friendly.

In electric lighting systems for discharge lamps such as fluorescent lamps and high-intensity-discharge lamps, a device known as “ballast” is used to control and limit the current in the lamp. The mainstream product, “electromagnetic ballast”, consists of a choke which is made of metal core and copper winding. It is highly reliable and has a typical lifetime of 15-20 years, with little maintenance required. The metallic choke is recyclable and is therefore environmentally friendly.

Professor Hui and Dr Chung developed a central dimming technology that can turn “non-dimmable” electromagnetic ballasts into “dimmable” ones. It is compatible with all electromagnetic ballasts and no major rewiring is required. Its dimming capability allows users to use lighting energy when and where it is necessary and to the appropriate lighting level. Each central dimming system can control up to 150-200 discharge lamps, so substantial reduction in electronic waste can be achieved. It has a “self-recovery” feature, that is, if the central dimming system fails, the lighting system will continue to work. “The novel technology is suitable for extreme weather conditions and requires very low maintenance cost,” said Professor Hui.

Lighting systems consume about 15 to 18% of global electricity. If the new technology is widely applied, it could reduce power consumption in electric lighting systems by 1/15 (or 6.7% in the lighting energy sector), thus reducing 1% of global electrical energy consumption annually. The central dimming control system has been tested in