A new structured thermal armour achieves liquid cooling above 1,000°C, overcoming challenge of Leidenfrost effect

Efficient cooling of hot surfaces is essential in different applications, from steel and aerospace industries to nuclear plants. But in physics, high temperature triggers the Leidenfrost effect, which makes liquid cooling on the hot surface ineffective. A research team led by scientists from City University of Hong Kong (CityU) has recently designed a structured thermal armour (STA) that achieves efficient liquid cooling even over 1,000°C, fundamentally solving a 266-year-old challenge presented by the Leidenfrost effect. This technology breakthrough can be applied in aero and space engines and beyond, including improving the safety and reliability of next-generation nuclear reactors.

The research has been led by Professor Wang Zuankai from CityU's Department of Mechanical Engineering (MNE), Professor David Quéré from the PSL Research University, France, and Professor Yu Jihong, Director of the International Center of Future Science, Jilin University and Senior Fellow of the Hong Kong Institute for Advanced Study at CityU.

The findings were published in the latest issue of the highly prestigious scientific journal Nature under the title “Inhibiting the Leidenfrost effect above 1,000 °C for sustained thermal cooling”. It was also highlighted in Nature News & Views.

A research team led by scientists from CityU has recently designed a structured thermal armour that achieves efficient liquid cooling even over 1,000°C.

Cause of ineffective liquid cooling on hot surfaces

The Leidenfrost effect is a physical phenomenon discovered in 1756. A common example in our daily life is that a drop of water will quickly evaporate if it drops on an iron plate hotter than 100°C, the boiling point of water. But if the iron plate’s temperature reaches the “Leidenfrost point”, the water drop will roll around on the iron plate and evaporate gradually, “surviving” longer.

This is because when liquid drops on a surface significantly hotter than the boiling point, a thermal insulating vapour layer is produced at once between the liquid and the super-hot surface. As a result, the liquid is levitated, preventing the liquid-solid contact. This dramatically reduces heat transfer performances at high temperatures, making liquid cooling on the hot surface ineffective. This effect is most often detrimental and it has remained a historic challenge to suppress this effect.

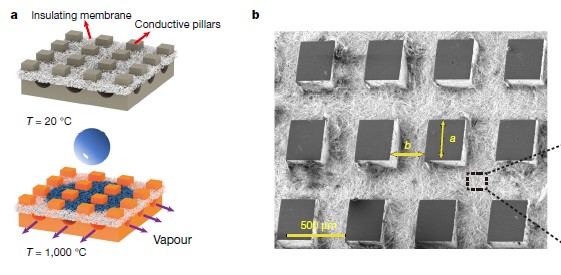

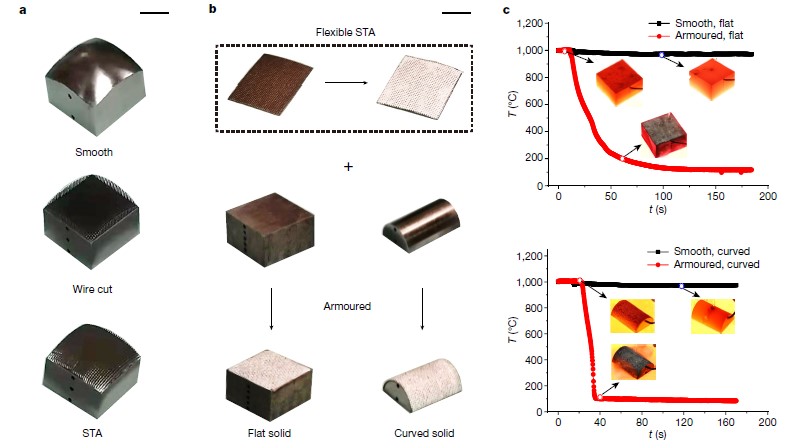

The CityU-led team solved this 266-year-old challenge by constructing the “structured thermal armour (STA)”, a multitextured new material with key elements that have contrasting thermal and geometrical properties. The rational design for the STA superimposes robust, highly thermally conductive, protruding steel pillars that serve as thermal bridges for promoting heat transfer; an embedded thermally insulating membrane designed to suck and evaporate the liquid; and underground U-shaped channels that evacuate the vapour.

The STA successfully inhibited the occurrence of the Leidenfrost effect up to 1,150 °C by transferring heat energy through liquid evaporation. Liquid superwetting that usually does not occur in extremely high temperatures was also observed. The research team discovered that STA achieves efficient and controllable cooling across the temperature range from 100°C to over 1,150°C, which is 600°C higher than previously attained.

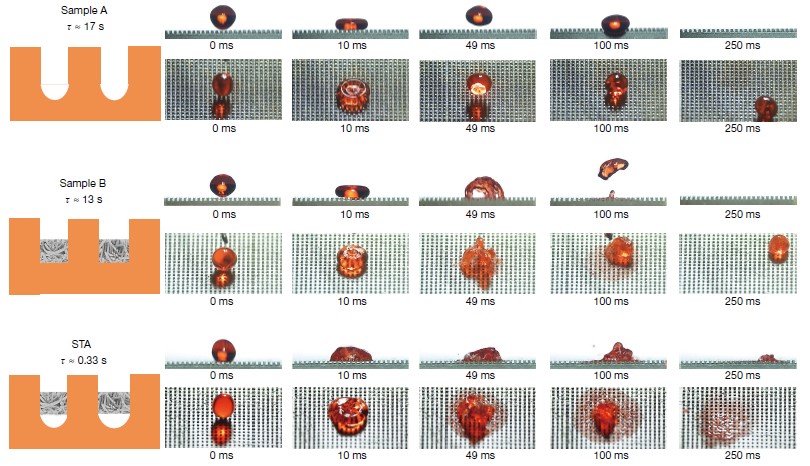

The STA consists of pillars, thermally insulating membrane and U-shaped channels. The team built two control samples to investigate its performance, one with pillars and U-shaped channels and the other with a membrane but no channels. The team then observed what would happen when orange-dyed water drops on the surfaces of the three samples, which were all heated to 1,000°C. They found that water on STA was constantly pinned and sucked by the membrane, which led to a lifetime of 0.33s, approximately 50 times faster than the other two samples. This means that heat energy was transferred quickly by evaporation and cooled the surface.

STA can be flexible and apply to different surfaces

“This multidisciplinary research project is truly a breakthrough in science and engineering, since it mixes surface science, hydro- and aero-dynamics, thermal cooling, material science, physics, energy and engineering. Searching for novel strategies to address the liquid cooling of high-temperature surfaces has been one of the holy grails in thermal engineering since 1756. We are fortunate to fundamentally suppress the occurrence of the Leidenfrost effect and thereby provide a paradigm shift in liquid thermal cooling at extremely high temperatures, a mission that has remained uncharted to date,” said Professor Wang.

Professor Wang pointed out that current thermal cooling strategies under extremely high temperatures adopt air cooling measures rather than effective liquid cooling owing to the occurrence of the Leidenfrost effect, especially for applications in aero and space engines, next-generation nuclear reactors, and devices used in extremely high temperatures. Their technology breakthrough holds the potential to apply efficient liquid cooling of extremely high-temperature surfaces to nuclear plants and help prevent nuclear accidents.

“The designed STA can be fabricated to be flexible, eliminating the need for additional manufacturing, especially for those surfaces that are hard to be textured directly. This is why the STA possesses huge potential for practical applications,” added Professor Wang.

Professor Wang, Professor Quéré and Professor Yu are the corresponding authors of the paper. The first authors are Dr Jiang Mengnan and Dr Wang Yang from MNE.

The collaborators are Professor Pan Chin, Head, Dr Steven Wang, Assistant Professor, Zhang Huanhuan, Research Assistant, Liu Fayu and Li Yuchao, PhD students, from CityU’s MNE; and Professor To Suet and Du Hanheng, PhD student, from the Department of Industrial and Systems Engineering, Hong Kong Polytechnic University.

The research was supported by the Research Grants Council of Hong Kong, the Tencent Foundation through the XPLORER PRIZE, the Hong Kong Innovation and Technology Commission, the National Natural Science Foundation of China and Programme of Introducing Talents of Discipline to Universities (the “111 Project”).

DOI number: 10.1038/s41586-021-04307-3