Advancing Sensing and Robotic Actuation Technology

To take sensing and robotic actuation technologies to new heights and application domains, a collaborative research team at CityU is working on developing next-generation three-dimensional (3D) sensing systems and 4D robotics actuators for applications in digital healthcare, medical robotics and extended reality.

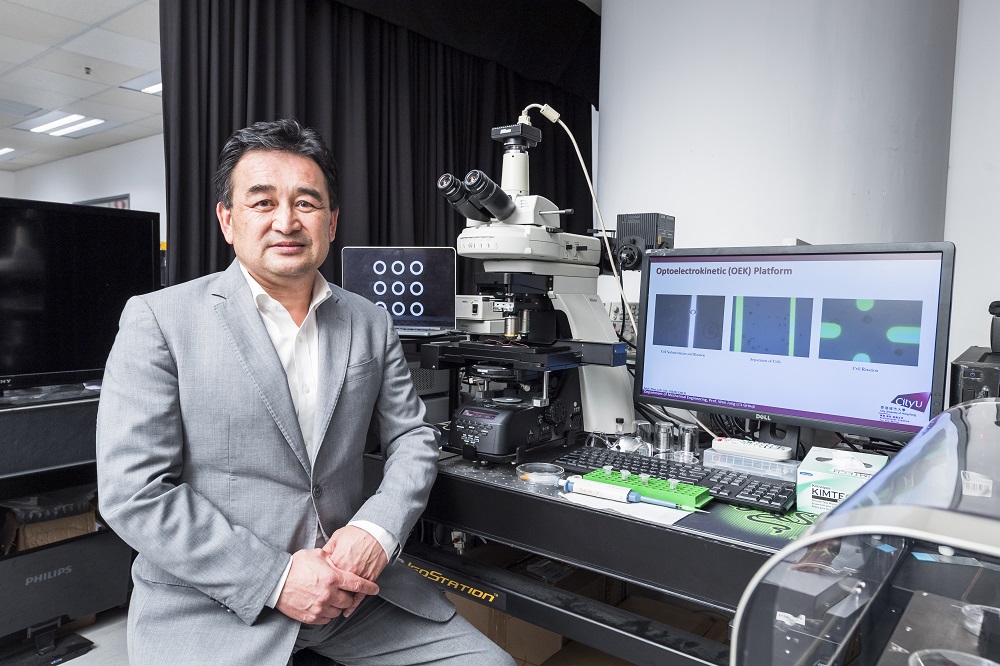

Professor Li Wen Jung, Chair Professor of Biomedical Engineering and Director of the Joint Laboratory for Robotic Research (JLRR), which was established by the Shenyang Institute of Automation, Chinese Academy of Sciences (SIACAS) and CityU, specialises in developing micro-electromechanical systems (MEMS) and various micro-, nano- and bio-sensing and robotics technologies.

MEMS is a process technology used to create tiny integrated devices that combine mechanical and electrical components. Ranging in size from a few micrometres to millimetres, these devices or systems can sense, control and actuate on a micro scale with high sensitivity and extreme accuracy, and generate effects on the macro scale. Based on integrated circuit technology, the batch fabrication capacity of MEMS devices enables low per-device production costs.

Fabricating sensors for health applications

Currently MEMS is widely used in applications such as actuators in inkjet printer nozzles, crash air-bag accelerometers in automobiles, projection display chips, optical switches, and blood pressure sensors. “In particular, micro-, nano- and bio-sensors are very important for digital and tele-medicines,” said Professor Li. “Doctors can use many different physiological sensors to conveniently monitor their patients. And all these sensors are based on MEMS fabrication technology in one way or another.”

His team has employed this widely used technology to fabricate a number of sensors for healthcare applications. One of their ongoing projects involves using flexible smart-skin sensors to decipher the correlation of a patient’s arterial pulse with kidney disease progression. They also deployed MEMS to fabricate microfluidics chips that separate and identify cancer cells and stem cells, contributing to the early diagnosis of diseases and biomedical science research.

One of their current research focuses involves leveraging the latest additive 3D nano-printing technology to develop next-generation 3D sensing and 4D robotic actuation systems.

“Additive 3D nano-printing technology can integrate complex geometric features, compact electronic circuits and many new functional materials into flexible or rigid polymers, enabling the design of novel single or multi-material micro/nano sensors and actuators to have features at multiple length-scales,” explained Professor Li.

Leveraging multi-material 3D nano-printing

Using an advanced 3D nano-printing system that can produce multi-layered nano-material-based structures and 3D circuitry in the JLRR at CityU, Professor Li and his team are developing flexible skin-sensors for integrating with assistive robots for the elderly, and for producing tactile sensors to enhance extended reality-based education in Hong Kong.

They will also modify the printing platform so that advanced sensing and conducting nanomaterials, such as graphene oxide, carbon nanotubes and other nanomaterials, can be embedded into 3D fabricated mechanical structures. This is expected to speed up the process of sensing device prototyping dramatically at lower cost.

Moreover, with multi-material 3D nano-printing, researchers can directly fabricate the functional body of robots, employing various soft material components with different degrees of stiffness, thus avoiding complex moulding techniques and assembly. By introducing new classes of customised materials and functionalities into 3D printing, they can fabricate new breeds of robotic actuators – 4D actuators – that are stimuli-responsive, self-morphing, and embedded with programmable architectures. The team plans to demonstrate the fabrication of several advanced actuation devices, including cell-electric-stimulation array for bio-syncretic robots, bio-syncretic cell-based actuators, and 4D micro-robots with fluorescent characteristics for biomedical applications.

“As a technologist, my research goal is very clear: develop technologies to advance human wellbeing, including extending human life, making everyday life more enjoyable, and discovering new phenomena,” said Professor Li.

This research article originated from CityU RESEARCH.