Elastic properties of nano diamond revealed for the first time

In a world’s first, an international research team led by City University of Hong Kong (CityU) has discovered that diamonds at nanoscale can undergo ultra-large, fully reversible elastic deformation, findings that could have a profound impact on the nanotechnology and biomedical fields, and even quantum information technologies.

Diamond is well-known for its brittle mechanical behaviour, viz., it fractures easily when subjected to relatively small amount of deformation. However, led by Dr Lu Yang, Associate Professor in the Department of Mechanical and Biomedical Engineering (MBE) at CityU, an international team of researchers demonstrated that when diamond was downsized to nearly 100 nanometres in diameter, which is about one six-hundredth of the size of human hair, up to around 9% of tensile elastic strain was recorded for single crystalline samples. The figure is very close to the maximum theoretically achievable strain for an ideal diamond crystal. In contrast, bulk diamond is usually regarded as “undeformable”, with only 0.1 to 0.35% strain was recorded in the past.

The team has also found that the deformation of the nanoscale diamond samples is fully-reversible in nature, which implies that the diamond material retains the ability to instantaneously revert back to its original shape when the force causing the deformation is withdrawn, meaning nanoscale diamond can be elastic.

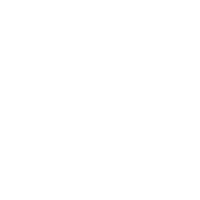

This ground discovery was published in the prestigious journal Science this week under the title “Ultralarge elastic deformation of nanoscale diamond”. It was jointly presented by Amit Banerjee and Zhang Hongti, two of the co-first authors of the paper supervised by Dr Lu. The research team comprises materials scientists and mechanical engineers from Massachusetts Institute of Technology (MIT), Ulsan National Institute of Science and Technology, and Nanyang Technological University.

After numerous overnight experiments, when the surprising result of elasticity in nanoscale diamond was first discovered in his lab, Dr Lu described the team’s feelings as “extremely exciting”.

“This finding would fundamentally change our common understanding of diamond,” he said.

The research holds great promise because diamond is compatible with the human body. One area of possible future exploration is diamond needle-based drug delivery to human cells. “Our discovery on nano diamond’s elasticity can help to make such intracellular delivery to be more durable, and cost-effective,” Dr Lu explained.

“The next generation of information technology could be also based on diamond. Nanoscale diamonds with well controlled point defects can be used for quantum computing and quantum information processing,” he added. “Our discovery concerning diamond’s nano-sized characteristics allows manufacturers to produce highly reliable and efficient diamond resonators and sensors for faster data storage and transfer. Future computers will be smaller, lighter and faster.”

This novel finding may pave the way for diamond’s practical applications in nanomechanical engineering, biomedical engineering, photonics, optoelectronics, and ultra-strength materials.

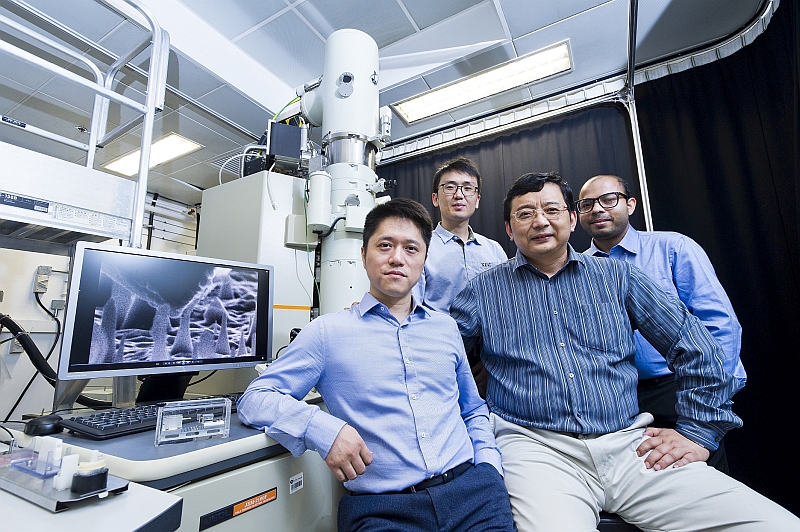

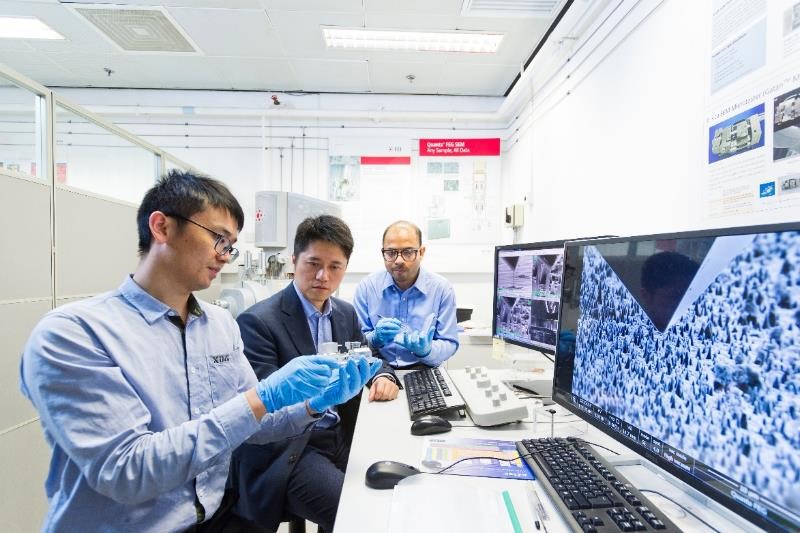

In this project, Dr Lu and his team aimed to characterise the mechanical properties of diamonds at nanoscale. Since diamond is the hardest natural material, it is often used for cutting and drilling tolls as well as to test other materials’ mechanical properties. To tackle the predicament of “diamond against diamond” for this unusual experiment, Dr Lu and his team made use of their unique in situ nanoindenter platform inside electron microscope in CityU to develop the novel “push to bend” test – to exert force onto the diamond nanoneedles from the slant surface of a nanoindenter diamond tip, and observe the bending of nanoneedles in a scanning electron microscope. “We have developed a unique nanomechanical approach to precisely control and quantify the ultralarge elastic strain distributed in the nanodiamond samples,” said Dr Lu. The nano diamond samples were fabricated by Professor Zhang Wenjun of the Department of Materials Science and Engineering at CityU.

Later, using these real-time bending experiment videos, combined with finite element method analysis supplied from MIT nanomechanics lab, the team evaluated the local stress, strain and displacement of the nanoneedle structures. Both “single-crystalline” and “poly-crystalline” needles of diamond have been observed to be able to achieve unexpectedly high elastic strain; and “single-crystalline” samples achieve a much higher strain, almost up to 9%. Using density functional theory-molecular dynamic (DFT-MD) simulations, the researchers evaluated that the observed highest strain values approached the theoretical maximum strain values achievable for an ideal defect-free diamond crystal, which is about 10%.

According to Dr Lu Yang, this large deformation should be mainly attributed to the paucity of defect in the crystal structure of the “nano-size” material (“size effect”), and its relatively smooth surface. “In addition, unlike metals, the sturdy covalent bonding in diamonds makes them highly resistant to plastic deformation,” he explains.

“This discovery is not only a nanomechanics breakthrough, but also opens the door for the emerging ‘elastic strain engineering’ of nano diamonds, by taking advantage of the drastically changed band structure under large lattice strains, in which their thermal, optical, magnetic, electrical, electronic, and chemical properties can be changed in significant ways,” Dr Lu added.

The research was funded by the Research Grants Council and National Natural Science Foundation of China.

The team also included Professor Lu Jian, Vice-President (Research and Technology) and Chair Professor of Mechanical Engineering, Dr Liu Jiabin and Yuen Muk-fung at CityU, Dr Dao Ming and Daniel Bernoulli at MIT in USA, Professor Subra Suresh, President of Nanyang Technological University in Singapore, and Dong Jichen and Professor Ding Feng at the Institute for Basic Science, Ulsan National Institute of Science and Technology in South Korea.

Related Story:

Four CityU scholars awarded HK$23m funding from RGC research fellow schemes