CityU material scientists discover a new mechanism to increase the strength and ductility of high-entropy alloys

A research team co-led by materials scientists from City University of Hong Kong (CityU) has recently discovered a new mechanism to increase the strength and ductility of a high-entropy alloy, two properties which normally vary inversely with each other. The findings provide important insights for the future design of strong yet ductile high-entropy alloys and high-entropy ceramics.

The strength-ductility trade-off is a longstanding issue for conventional alloys that are usually based on one or two principal elements, meaning that increasing the strength usually sacrifices ductility. In the past decade, a new alloy design strategy was proposed: mixing multiple elements to form alloys, termed “multi-principal element alloys” (MPEAs) or “high-entropy alloys” (HEAs). MPEAs exhibit excellent mechanical properties, such as both great ductility and superb strength.

These excellent mechanical properties are believed to originate from severe atomic lattice distortion caused by the random mixing of multiple principal elements with distinct atomic sizes, bonding variations, and crystal structure differences, which in turn lead to a “heterogeneous lattice strain effect”. However, the heterogeneous lattice strain field (a strain field refers to the distribution of strain through part of a body) is difficult to quantify and characterize, so its impact on strengthening alloys via three-dimensional (3D) dynamic dislocation has been ignored until recently.

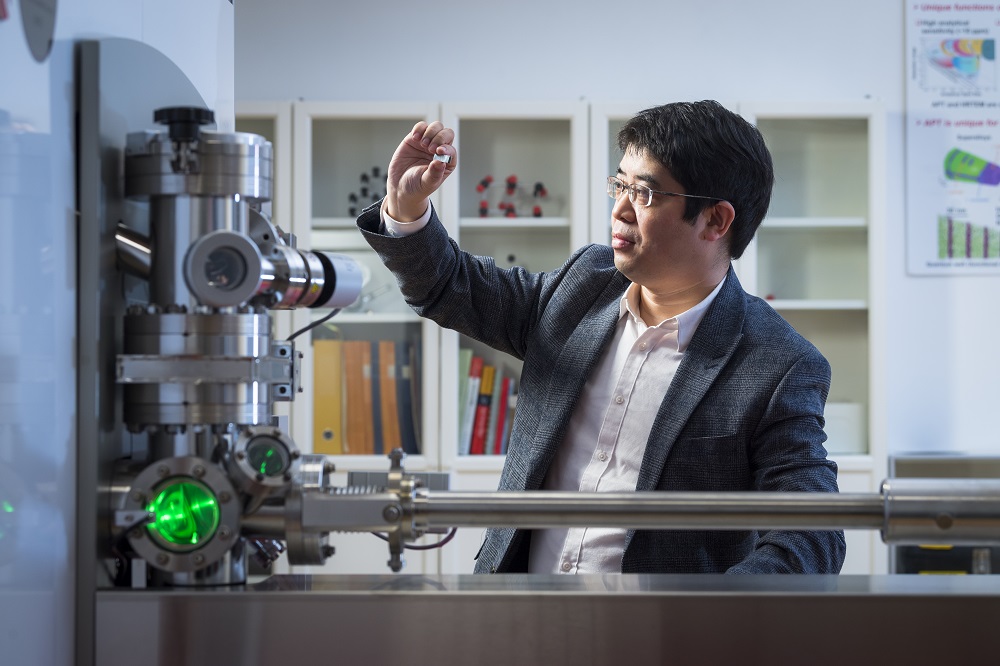

But the latest experiments and a series of simulations done by the research team co-led by Professor Yang Yong, in CityU’s Department of Mechanical Engineering, and Professor Fang Qihong, at Hunan University, show that the heterogeneous strain field could contribute to the enhanced mechanical properties of MPEAs through the new heterogeneous strain-induced strengthening mechanisms, leading to strength-ductility synergy in the alloys. Their findings were published in the scientific journal The Proceedings of the National Academy of Sciences (PNAS) under the title “Heterogeneous lattice strain strengthening in severely distorted crystalline solids”.

“Materials science and engineering textbooks traditionally list four ductility-strengthening mechanisms: dislocation strengthening, solute strengthening, grain boundary strengthening and precipitation strengthening,” explained Professor Yang. “This textbook knowledge has been taught for hundreds of years in universities to students majoring in materials science, mechanical engineering and applied physics.” “Now we have discovered a new ductility-strengthening mechanism through experiments and numerical simulations, which we call ‘heterogeneous lattice strain strengthening’.”

Unlike traditional strengthening mechanisms, which usually lead to a strength-ductility trade-off, this newly discovered strengthening mechanism promotes strength-ductility synergy, which means researchers can increase the strength and ductility of a high-entropy alloy at the same time. “The new findings help explain many recent findings whose mechanisms are under debate and guide the development of new strong, yet ductile metals and ceramics,” Professor Yang added.

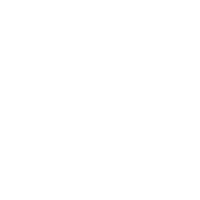

Video showing the effect of lattice strain field on the dynamic evolution of dislocations under uniaxial tensile loading by DDD simulations; the colour lines represent the dislocation on different slip planes. Video source: Li, Jia et al. / doi.org/10.1073/pnas.2200607119

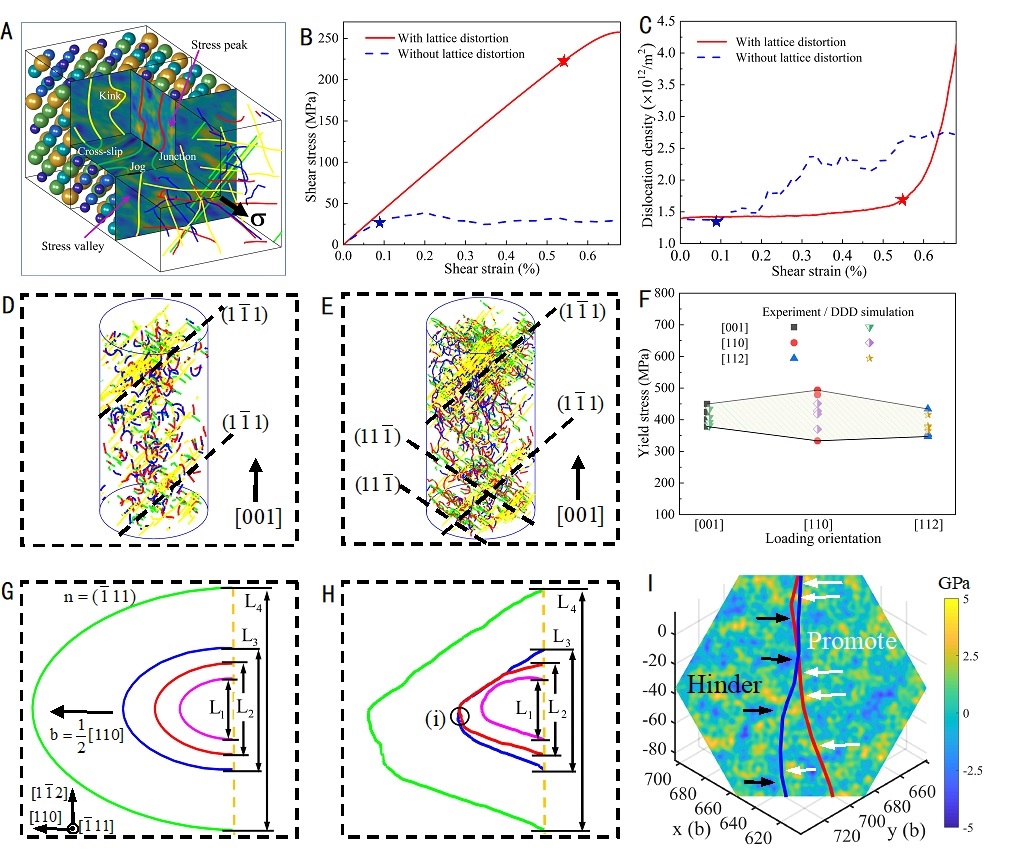

In the experiments, the research team first characterized the lattice strains in the high-entropy alloy FeCoCrNiMn using techniques like geometric phase analysis (GPA) based on high-resolution transmission electron microscopy (TEM). It then performed micropillar compression tests to study how dislocations glide and cross slip in the alloy. Next, the team performed extensive discrete dislocation dynamics (DDD) simulations by incorporating the lattice strains measured experimentally.

The experiments showed that the lattice strain not only restricted the dislocation motion, thus improving the yield strength, but also promoted dislocation cross slips to enhance ductility. The findings demonstrated the significant effect of the heterogeneous strain field on the mechanical properties of the alloy. They provide a new perspective to probe the origin of the high strength of high-entropy alloys and open up new avenues for the development of advanced crystalline materials.

The combined efforts of the experiments and computer simulations revealed the physical mechanisms that underpin the strength-ductility synergy observed in the experiments. “The findings of this study provide a fundamental mechanism to overcome the strength-ductility trade-off facing traditional alloys,” said Professor Yang.

Photo credit: City University of Hong Kong

The first authors are Dr Li Jia and Dr Chen Yang, from Hunan University, and Dr He Quanfeng, of CityU (the then-PhD student of Professor Yang). Other collaborators include Professor Liu Chain-tsuan, University Distinguished Professor in the College of Engineering of CityU, Professor Peter K. Liaw, from the University of Tennessee, USA, and Professor Liu Yong, from Central South University. The key funding sources were the General Research Fund and the National Natural Science Foundation of China (NSFC).