Skin-inspired tactile sensors distinguish diverse stimuli and offer hope for limb injuries

Imagine an advanced robotic hand that can grasp a fragile piece of tofu without crushing it! A research team co-led by researchers from City University of Hong Kong (CityU) has developed an innovative tactile sensor with super fast response time and high sensitivity. It can distinguish different external stimuli in real time, with the potential to be applied to electronic skin and smart prosthetics. It can offer hope to people with physical disabilities or severe limb injuries to regain their sense of touch and improve their quality of life.

The study was co-led by Dr Yang Zhengbao, Assistant Professor in the Department of Mechanical Engineering of CityU, and his collaborator, Professor Hu Hong from Harbin Institution of Technology, Shenzhen. Their findings have been published in Advanced Science under the title “Skin-inspired Piezoelectric Tactile Sensor Array with Crosstalk-free Row+column Electrodes for Spatiotemporally Distinguishing Diverse Stimuli”.

Inspired by human skin

The natural skin gives the human body a sense of touch that simultaneously sense the intensity and pattern of various external stimuli, such as sensing the magnitude of pressure or gripping force. For example, if we feel a bottle slipping in our hands, we will adjust our grip on the bottle to prevent it from falling. However, current tactile sensors that mimic human skin often cannot immediately sense and distinguish different external stimuli, such as whether they are sliding or pressing. So even equipped with tactile sensors, the existing robotic hands are still not as agile as human hands.

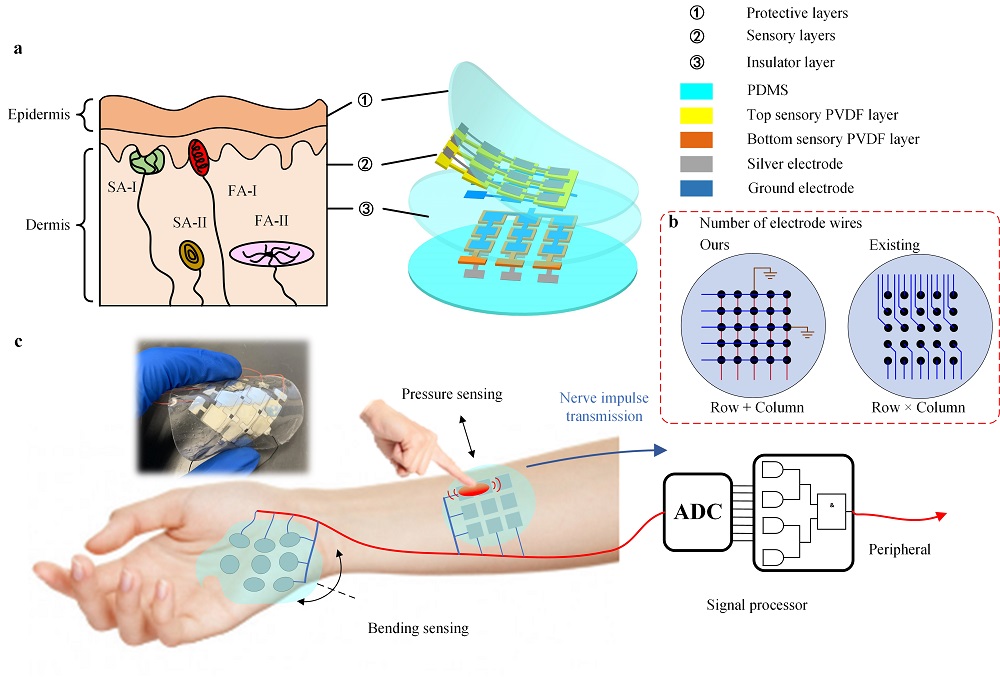

To improve these sensors, and inspired by the miraculous structure of human skin, Dr Yang and his research team colleague recently fabricated a dual-layer comb piezoelectric tactile sensor array that can distinguish the magnitude, exact position, and pattern of different external stimuli in real time.

Response time: 10 milliseconds

The new technology sustains higher sensitivity, long-term durability, and faster response time than similar devices. “The system can achieve real-time detection and differentiation of diverse external stimuli within one sensor element. Our sensor can respond extremely fast, with response time down to 10 milliseconds, which is even faster than human skin,” said Dr Yang.

The new tactile sensor array consists of protective layers, an insulative layer, and two piezo sensory layers. “This architecture enables the sensor to measure more spatiotemporal information in and out of a plane,” he explained.

Piezoelectricity refers to the exchange of mechanical and electrical energy in dielectric materials. Based on the piezoelectric effect, the team's piezoelectric film-based tactile sensor array converts external stimuli into electrical signals. The signals are then processed and combined with a logical algorithm to instantly determine the magnitude and pattern of external stimuli, such as slight sliding, pressing, and bending.

A design avoiding signal crosstalk

Their experimental results have demonstrated that the sensor array can “sense” both the radius and direction of the bend, as well as accurately capture the exact location of multiple external stimulus points at the same time.

To minimise the size of the sensor, the team also invented a “row + column” electrode pattern instead of the existing 'row x column' electrode pattern, resulting in a significant reduction in the number of connections required. It can not only save costs but also solve a common signal crosstalk problem with existing sensors.

Grasp a piece of tofu without breakage

The research team conducted experiments to test the application of the sensor array. It showed that the robotic hand equipped with the innovative tactile sensor could adjust its force in time to get real-time feedback and successfully grasp the fragile tofu without crushing it. In contrast, the robot without the tactile sensors crushed the tofu.

The robotic hand equipped with the tactile sensor successfully grasps the fragile tofu without crushing it. (Video provided by Dr Yang’s team)

The robotic hand without the tactile sensors crushed the tofu. (Video provided by Dr Yang’s team)

This shows the sensor has great potential for the human-machine interface and promoting the development of smart prosthetics, robotic hands, and handling multiple soft and fragile products in the industry.

In addition, it is a promising candidate for reconstructing the human tactile system by re-establishing tactile sensation for people with skin damage and assisting amputees. The sensor can also help monitor overall human health, accurately detecting weak artery pulses. Dr Yang added that this new technology is even sensitive enough to detect the rapid movement of a tiny spider which is just 5mg in weight.

“Our work fills the gap of existing sensors for sensing and distinguishing diverse stimuli in real time. This paves the way for an emerging area of piezoelectric sensor design and large-area scalable fabrication,” Dr Yang concluded. “Its application is versatile and can be used for electronic skin, health monitoring, and robotics.”

The first authors of the study are Lin Weikang and Wang Biao, research assistant and PhD student from MNE respectively. Dr Yang and Professor Hu are the corresponding authors. Other team members include Shan Yao, PhD student from MNE, and researchers from Harbin Institution of Technology, Shenzhen.

The research was funded by CityU, Hong Kong Research Grants Council and the National Natural Science Foundation of China.

DOI number: 10.1002/advs.202002817