The Impact

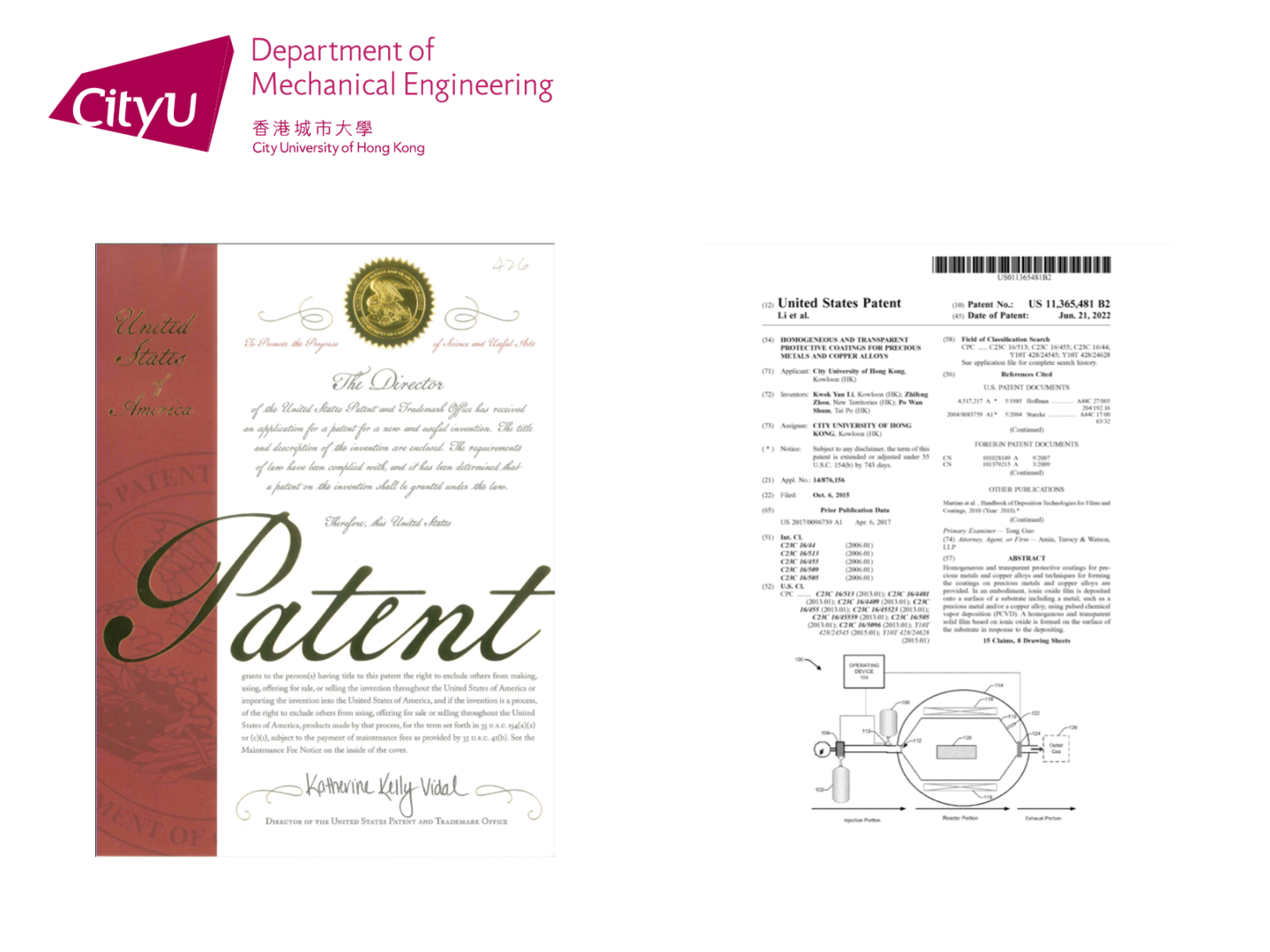

Prof. LI Kwok Yan with his team, Dr ZHOU Zhifeng and Dr SHUM Po Wan, has successfully granted a patent by the US Patent and Trade Office. The patent concerns a novel coating method for precious metals. The research was done in the Advanced Coatings Applied Research Laboratory (ACARL) and sponsored by The Federation of Hong Kong Watch Trades & Industries Ltd and the HKSAR ITC funding.

The new coating method, Pulsed CVD (modified from Metalorganic Chemical Vapor Deposition), has been developed, and the project has met all the deliverables set out at the beginning. The coating is optically transparent, has superior chemical resistance and could reach a hardness that exceeds sapphire (9) - all at once. The results have been presented in Baselworld (a well know, prestigious, annual international event for the watch industry). Above all, the new coating technology is suitable for production in scale and has great potential to become a 'must have' tool of trade in high-end watchmaking.

The Why

In the art of watchmaking, precious metals such as gold are the material of choice due to their rarity and natural colour. However, watches also need to withstand day-to-day wear and tear. Precious metals such as gold are soft metals which prone to deform and wear out. Further, for such use cases of precious metal, it also needs to be chemically inactive to outside influence; sweat, chemical substances and moisture. For those reasons, a coating is applied as a means of protection.

Yet, the problem with the current coating methods for precious metals has two weaknesses. First, traditional coating such as electroplating and organic coating would alter the natural finish of the precious metal - and so detracts the original purpose of using such metals. Second, PVD (physical vapour deposition) coating suffers from surface defects such as 'pinholes' and 'droplets.' And it is not suited for complex shape coating due to the directional nature of the deposited particles.

That is why a new coating method has been developed and successfully solved both weaknesses.