Opportunity

In fields such as flexible electronics, microfluidic devices, soft robotics and the fabrication of artificial tissues/organs, hydrophilic and hydrophobic materials have to be linked for various systems to function. By far the most common approach is chemical bonding, which “glues” two materials together. However, such chemical treatment can have harmful effects on the human body, such as inducing tumours, and is only suitable for use with relatively tough materials. There is thus a need for a novel method of linking soft hydrophilic and hydrophobic materials that does not pose a threat to human health. This invention presents just such a method: hydrophilic–hydrophobic hybrid structures are produced via 3D printing, which does not involve harmful chemical “glue” and improves the mechanical integrity of the linked structures.

Technology

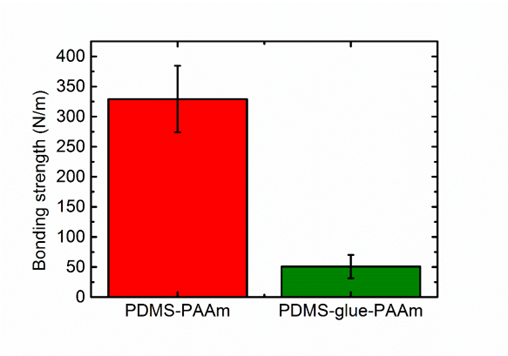

The invention is a novel fabrication method that links soft hydrophilic and hydrophobic materials to form hydrophilic–hydrophobic hybrid structures via 3D printing, as an alternative to chemical bonding. In the process of 3D printing, the hydrophilic and hydrophobic materials are physically entangled with each other. This creates a special interfacial structure that changes the fracture mechanism and increases mechanical integrity. As a result, fragile as well as tough materials can be linked together using this method, and the resulting structures are stronger than those created using chemical “glues” such as agar and gelatin. The ability to create strong hybrid structures by linking soft materials is very important in fields such as soft robotics and the fabrication of artificial tissues/organs.

Advantages

- 3D printing technique allows construction of physically entangled hydrophobic-hydrophilic hybrids which mimics biological structure.

- 3D printed hydrophobic-hydrophilic hybrid shows significantly higher bonding strength than chemically glued hybrid.

- 3D printed hybrid does NOT depend on the chemical structures of the glue or either component in the hybrid. Therefore, it can be applied to combine much more diversified materials.

- Free of chemical treatment, 3D printed hybrid is safer to human and more environmental friendly than chemically glued hybrid.

Applications

- Fabrication of flexible electronics devices

- Fabrication of microfluidic devices

- Soft robotics applications

- Fabrication of artificial tissue/organs