Traditional OLED generally consists of a pure metal or alloyed metal such as aluminum (Al), calcium (Ca) or magnesium–silver (MgAg) as a cathode. These electrodes provide highly reflective surfaces, and therefore there is a reduction in display contrast due to the reflection of ambient light by the highly reflective cathode. This problem becomes particularly serious for out-door display applications under strong ambient light. To improve display performance, a non-reflective or black backing layer for the display is highly desirable to increase the display contrast and also provides a pure black image element. Traditional LCDs are installed with backlights, thus the black display background is basically provided by two polarizers. The output of the backlight is controlled by the orientation of the liquid crystal that is sandwiched between the polarizers. The use of polarizers not only reduces the light output but also complicates the construction of the display system and increases the production cost. In contrast, OLEDs are self-emitting, and the black display background can be implemented by other means. For OLED displays, one simple solution for providing the black display background is to use a black, non-reflective surface. By using a light-absorbing film between the organic and metal cathode layers, the reflection of the ambient light can be greatly reduced, thus increasing the display contrast ratio. This contrast-enhancing feature is particularly important for daylight readable applications, such as display panels of cell phones, digital watches, digital cameras, out-door information boards, dashboards in automobiles, aircrafts and military air-fighters, etc.

CityU introduce two methods to improve the contrast ratio in OLEDs. First, we dope the oxygen-deficient silicon monoxide (SiO) into aluminum (Al) to form a light-absorbing, black-colored compound, Al2Ox<3. Second, we employ the use of a single-layer Sm:Ag cathode.

To cite Sm:Ag as an example, with the use of Sm:Ag as a black cathode the performance of the devices remains comparable to that of traditional devices with the Mg:Ag cathode in terms of brightness, electroluminescence efficiency, and turn-on voltage. But the contrast ratio of the device with Sm:Ag cathode (390:1) is eight times better than that of the traditional device with the Mg:Ag cathode. Sm:Ag, easily fabricated via simple thermal evaporation, was investigated as a single-layer light-absorbing cathode to increase the contrast ratio of organic light-emitting devices (OLEDs).

Organic photovoltaic (OPV) device has received considerable attention because of its potential for low-cost solar energy conversion. In the past couple of decades, many smart device configurations and high-performance materials have been used to improve the photovoltaic performance. Quantum efficiency of OPV devices depends on the absorption efficiency ( A), exciton diffusion efficiency (

A), exciton diffusion efficiency ( ED), and charge collection efficiency (

ED), and charge collection efficiency ( CC) at the electrodes. Absorption efficiency of incident photons can be simply increased by using thicker photoactive layers. However, exciton diffusion length invariably limits the thickness of the photoactive layer. Only photons absorbed within the exciton diffusion length from the donor/acceptor interface can survive the transport to the interface to subsequently dissociate into free charge carriers with a high yield. The inherent trade-off between the

CC) at the electrodes. Absorption efficiency of incident photons can be simply increased by using thicker photoactive layers. However, exciton diffusion length invariably limits the thickness of the photoactive layer. Only photons absorbed within the exciton diffusion length from the donor/acceptor interface can survive the transport to the interface to subsequently dissociate into free charge carriers with a high yield. The inherent trade-off between the  A and the

A and the  ED poses an upper limit of power conversion efficiency (

ED poses an upper limit of power conversion efficiency ( P).

P).

| Silicon | Organic | |

|---|---|---|

Max.  p(%) p(%) |

24% | 5.7% |

| Advantages | - High power efficiency | - Ultra-low production cost

- Lightweight - Transparent and flexible |

| Disadvantages | - Expensive

- Difficult to produce large area modules - Shortage of silicon |

- Still low efficiency |

| Latest Development of Red, Green and Blue Materials. Those Synthesized by UDC are Phosphorescent Materials | ||

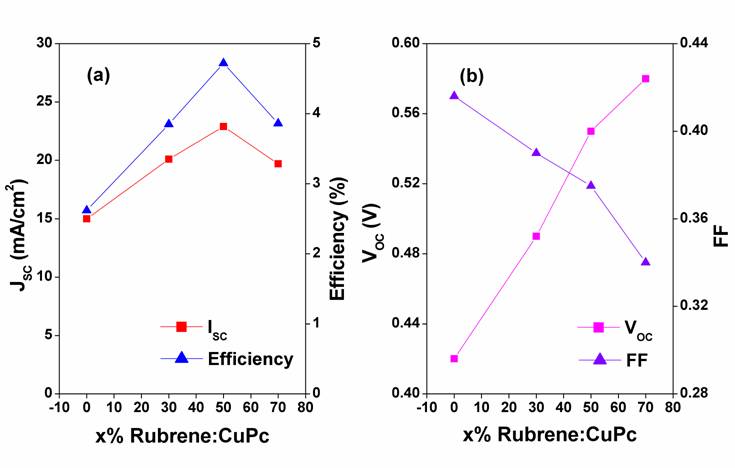

CityU exhibit that the performance of OPV could be dramatically enhanced by doping suitable fluorescent dyes into the donor and/or acceptor layers. By doping rubrene into standard CuPc/C60 OPV cell, a high JSC of 30.1 mA/cm2, VOC of 0.58 V, and an exceptionally high power conversion efficiency of 5.58% are achieved. The performance improvement is mainly attributed to efficient light absorption by rubrene in the range of 460–530 nm where two hosts have low absorbance, leading to more effective exciton formation. Their findings motivate the use of fluorescent dyes for maximizing absorption spectral coverage as well as increasing photon harvesting.