Opportunity

The development of manufacturing of high-temperature structural materials, including ceramics, glass, and metals, is limited by the extremely high melting points of material candidates and the challenging process of building complicated structures. Four-dimensional (4D) printing of elastomer-derived ceramics has provided tremendous breakthroughs in terms of the geometrical flexibility of ceramics. However, current commercial ceramic manufacturing systems have several major limitations that present opportunities for novel research. First, their processing steps are tedious and time-consuming, as they involve separate transformations of shape and material. Second, programming systems for ceramic manufacturing today are rough and lacking in accuracy, involving a mechanical stretch device for prestress engineering. Finally, they have a long polymer-to-ceramic transformation time.

Technology

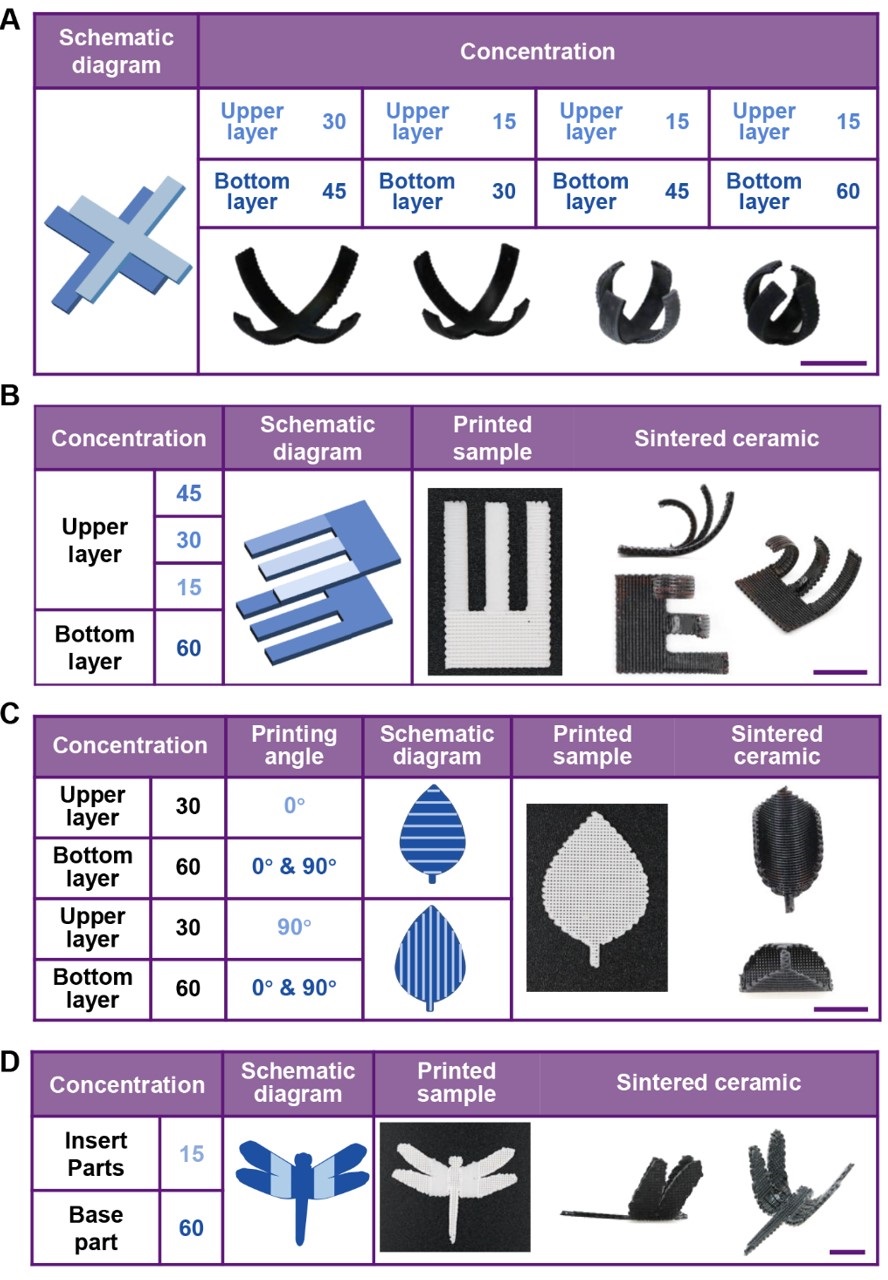

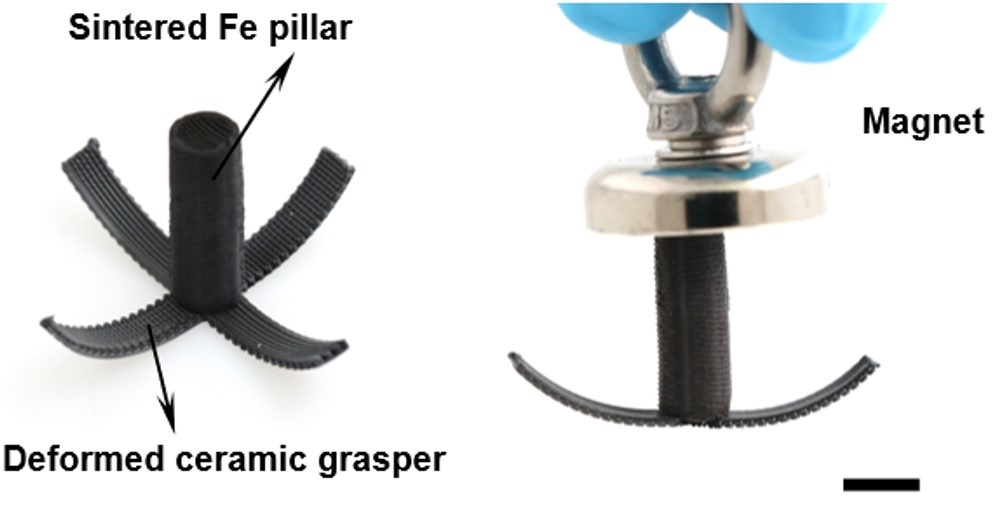

Researchers have developed a novel direct 4D printing technology to simply and easily achieve and precisely control the manufacturing of complex ceramics architecture. The system can be free-standing, without extra fixtures, and only three steps are involved: printing, curing, and sintering. The inks for 4D printing are prepared by mixing polydimethylsiloxane (PDMS) with different amounts of alumina nanoparticles. A multi-jet printer is used to print a bilayer gradient structure, with each layer consisting of ink with different ceramic mass fractions. During the sintering process, ink with different concentrations undergoes different degrees of shrinkage, resulting in the tunable mismatch of the bilayer structure and achieving the targeted geometry accurately by the regulation of ink concentrations..

Advantages

- Lower cost

- Faster and more precise control of construction of complex ceramics architecture

- Better suited to modern production lines

Applications

- The 4D printed dual-phase nano-ceramic backs manufactured by this technology will be used in the next generation of 5G communication terminals, which will have the advantages of low cost, high performance and long shelf life.

- Technology well suited to production lines for cell phones and laptop cases.