Opportunity

Energetic materials (EMs) including propellants, explosives and pyrotechnics are being widely used in civilian field (e.g. automobile airbags, mining, off-shore drilling, joining of materials by localized heating, metal cutting), as well as military fields (e.g. arms fire, safety and arming devices used in missiles or rockets). For good measure, nanoscale energetic materials (nEMs) have enlightened performance on improved energy release compared with traditional EMs (e.g. gun powder and trinitrotoluene (TNT)). Nevertheless, the performance of nEMs will be substantially reduced in the presence of water, for example, moisture in the air or underwater. Accordingly, waterproof nEMs or structures which allow the use of nEMs under situation with high moisture and/or water content show heightened interest.

Technology

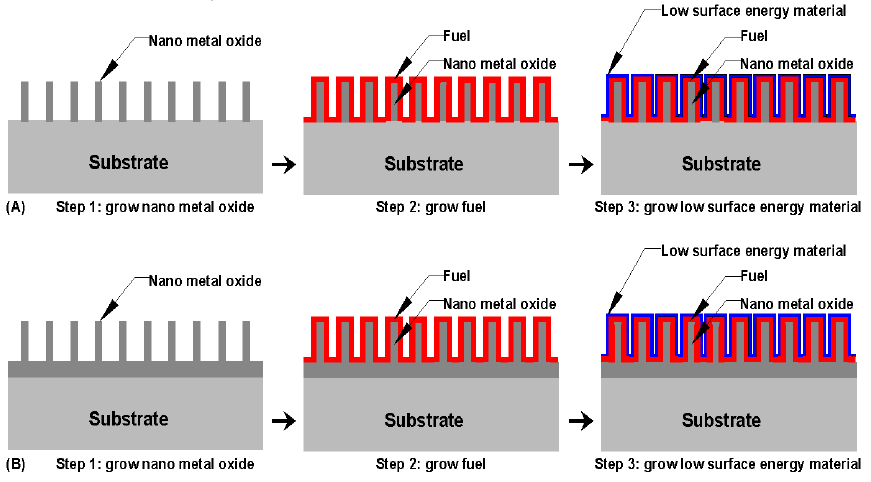

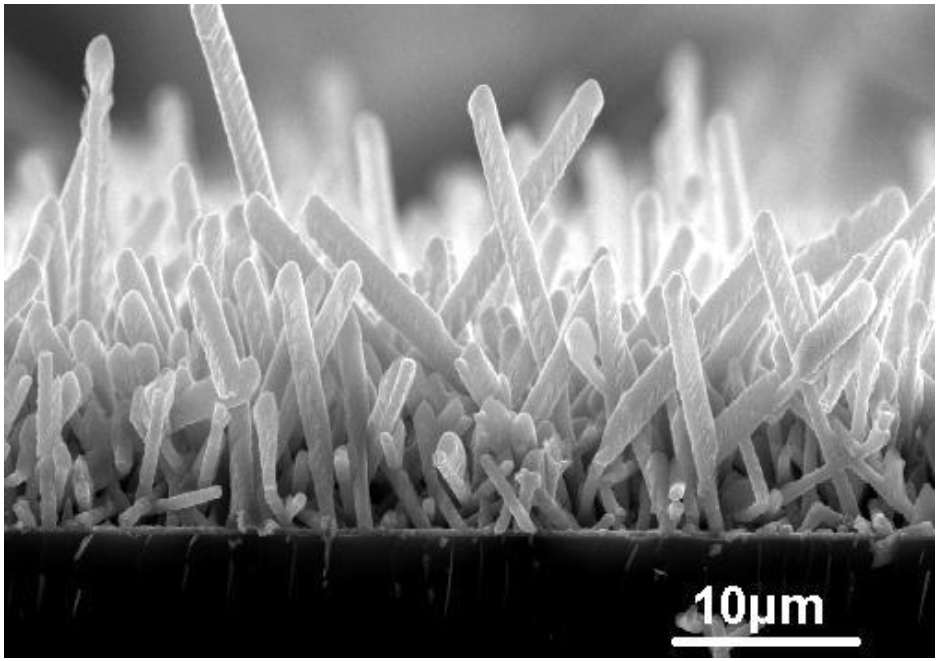

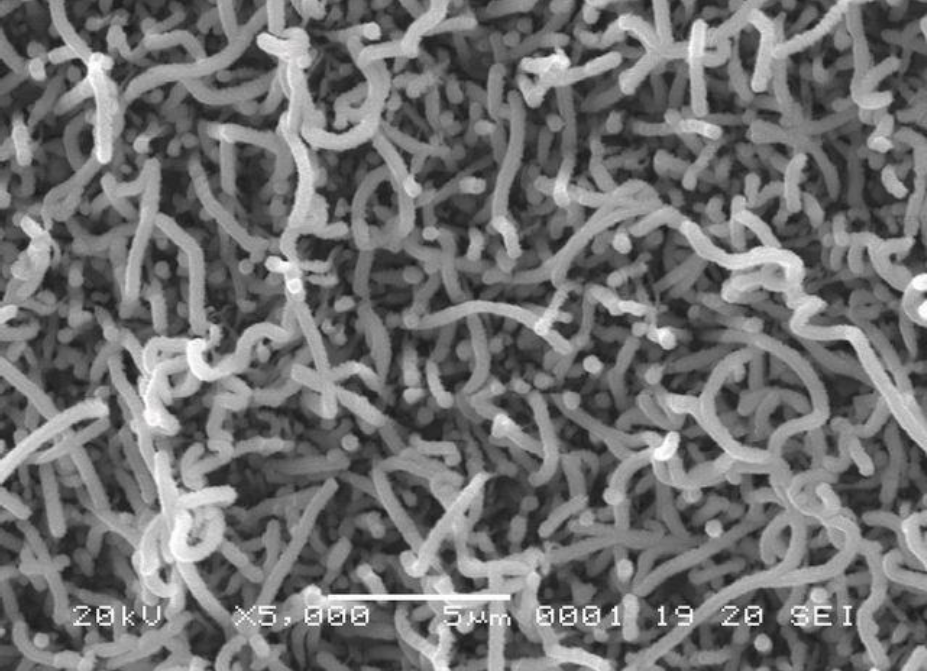

This invention depicts a method for fabricating waterproof nanoscale energetic material (nEM) arrays having sandwich structure by forming a metal oxide layer (e.g. Co3O4, CuO) of nanoscale structures in the form of elongated shape on silicon substrate, covering the metal oxide layer with a fuel material (e.g. aluminum and/or magnesium), and then applying hydrophobic material (e.g. fluoroalkylsilane) as the outermost layer to incorporate waterproof properties. Advantageously, the nEMs sandwiched between silicon substrate and waterproof material are capable of preventing moisture and/or water from interacting with the nEMs before and during heat generating exothermic reaction of nEMs, so that the nEMs can be used in humid environment or under water. Accordingly, the waterproof nEM arrays are suitable for long term storage and have excellent performance including low ignition temperature, high heat release, high gas generation, and fast reaction propagation rate.

Advantages

- Facile method to prepare the nanoscale energetic material arrays

- Waterproof property suitable for long term storage

- Excellent performance including low ignition temperature, high heat release, high gas generation, and fast reaction propagation rate

Applications

- Civilian application

- Military application

- Nanoscale energetic materials for underwater application

- Application of nanoscale energetic materials in environment with high humidity