Opportunity

Si-based devices are current-voltage devices, so it requires electric charges to flow in and out of the circuitry. During the fabrication of RDL circuit, the etching process is necessary to remove the exposed sputtered Cu seųed layer and Ti barrier layer, which inevitably will induce roughness of the Cu surface of the RDL at the same time. As the post-plating resting time (q-time) increases, the copper oxide surface makes the surface roughness worse after etching process. As a matter of fact, this surface roughness becomes a critical component for sheet resistance and contact resistance when the RDL linewidth shrinks under 10mm. We proposed a composite Cu structure for RDL, in which fine grains and nanotwins coexist to achieve high structural stability. Structurally stable copper can effectively resist surface corrosion and minimize copper surface damage even after a long q-time, offering a promising solution for superior RDL in advanced packaging technologies.

Technology

Typical manufacturing process for RDL, Copper is electroplated into the trenches and via holes simultaneously. After PR removal, the liner and Cu seed layer are removed by two etch processes, respectively. Meanwhile, the top surface of Cu of RDL is inevitably etched and roughened. It shows the q-time issue in real production, a non-protective oxide would grow on the Cu RDL surface, becoming the main source and sink of vacancies for surface roughness in etching process. This invention combines and optimizes to form a composite Cu structure in which fine grains and nanotwins coexist shows that the Cu exhibits the resistance of corrosion in RDL process that can also achieve both superfilling capability and structural stability without self-annealing effect.

Advantages

- The resistance of corrosion in RDL process

- Potential opportunity in advanced IC packaging technology

- Superfilling capability and structural stability

- No self-annealing effect

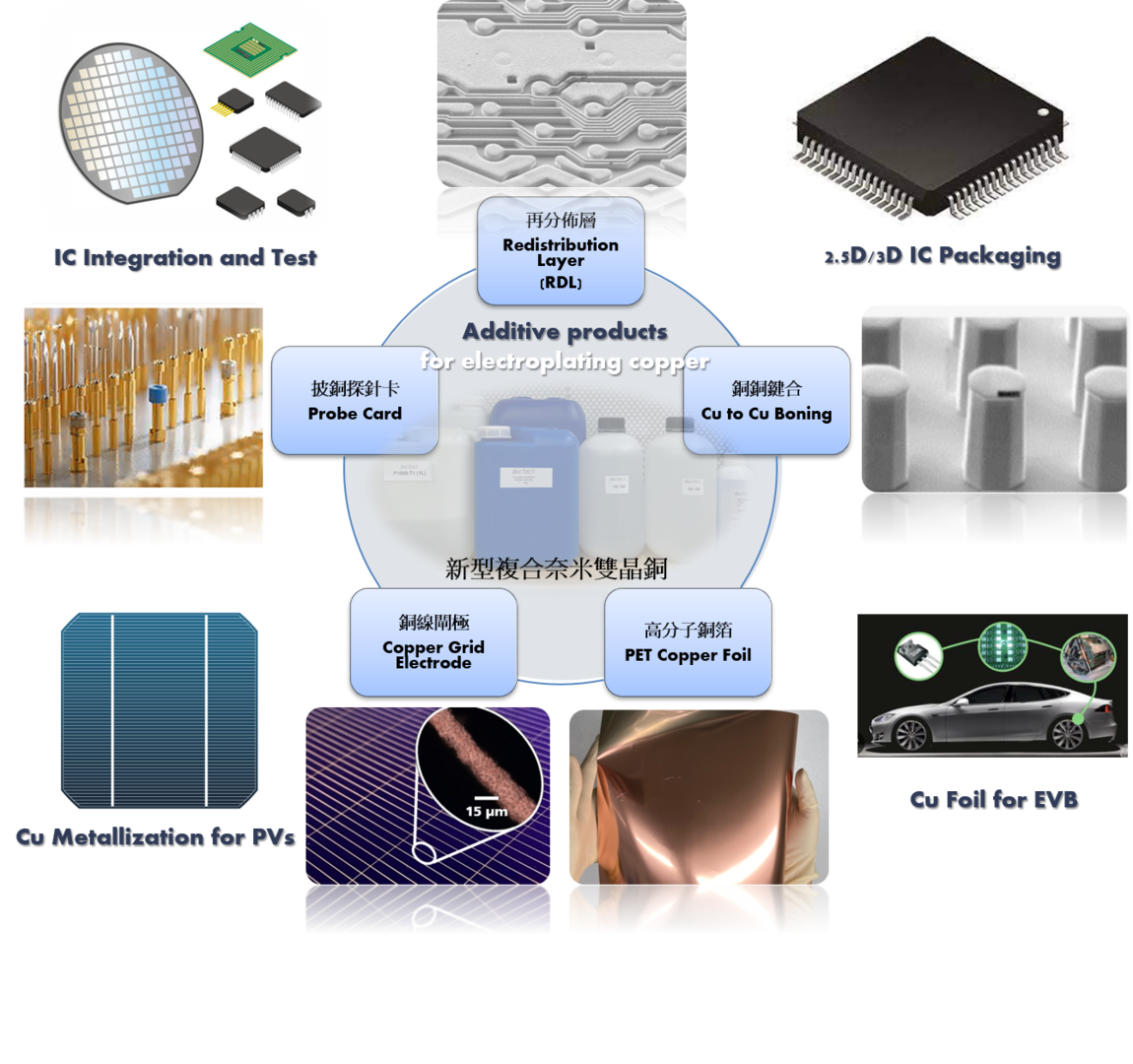

Applications

- 2.5D/3D IC packaging

- Cu to Cu Bonding

- Fine Pitch Redistribution Layer