Opportunity

Compared with 3D materials, 2D materials with atomic thickness have many unique properties and show great potential in many application fields. Based on a research from MMR, it is expected that the 2D materials market will have an annual growth rate of 3.9% in the next few years and the market size will reach 3.08 billion dollars in 2029. Among the different end-use application, semiconductors and electronics are the most potential market for 2D materials. It is expected that 2D materials can be a promising candidate for next-generation semiconductor devices due to its unique natures such as ultrathin layer and high charge mobility. However, one of the critical issues that limits the practical application of 2D materials is the device fabrication technique, especially the transfer process of 2D materials. In the conventional transfer methods, the 2D materials are highly contaminated, which deteriorates the electronic device performance.

Technology

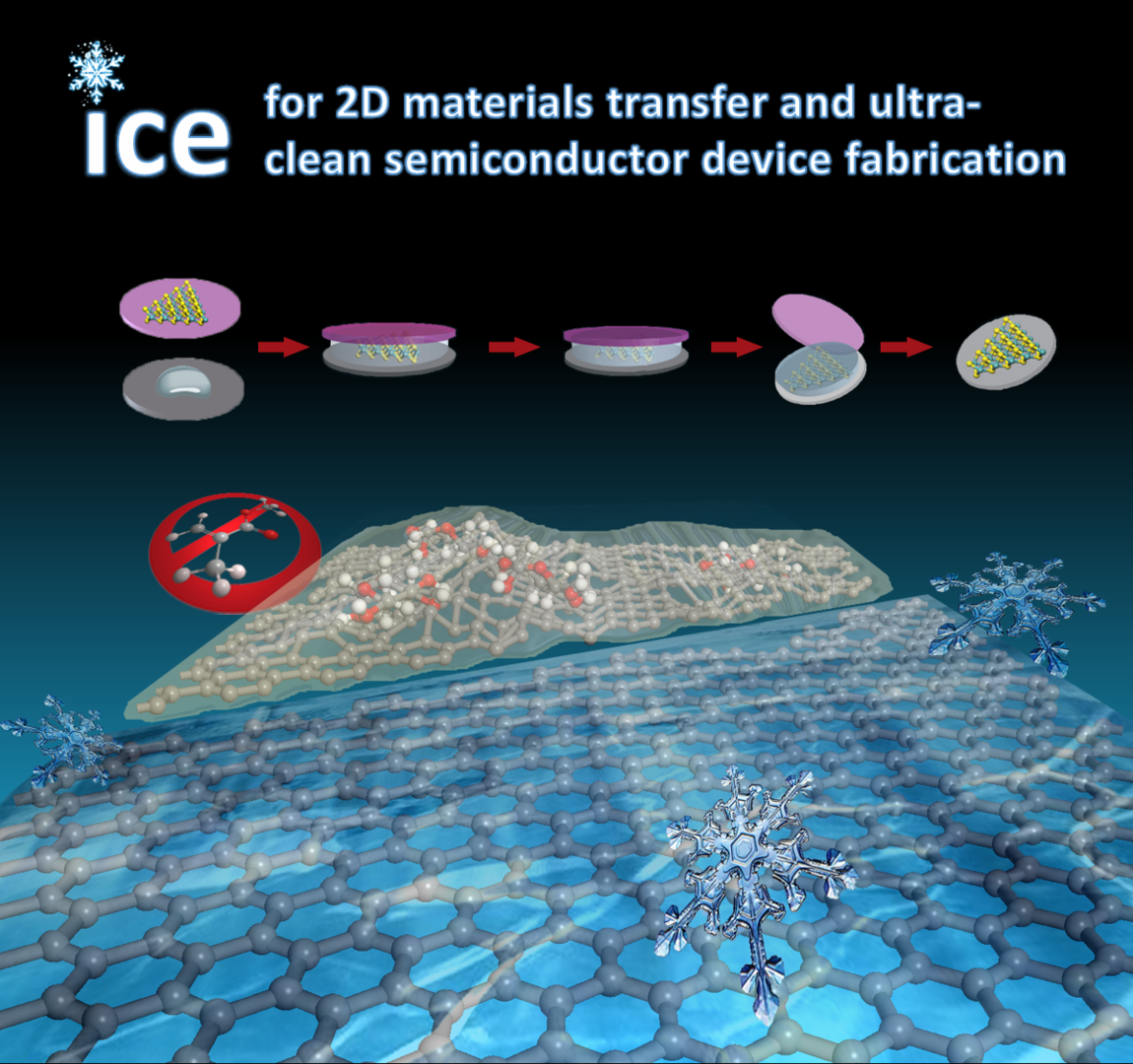

Here we propose our ice transfer technique, in which ice is the only materials used in the transfer process. Because no contaminants is induced, the 2D materials transferred by ice have a much cleaner surface and higher electrical performance than that transferred by conventional methods. And similarly, in our ice-cleaning technique, the ice is used as a cleaning stamp to clean 2D materials. Different from the ice transfer, a relatively higher temperature is used to reduce the adhesion of ice, which can protect the sample while removing the surface contaminants. Compared with other cleaning method, the ice cleaning technique is a universal, damage-free, and large-scale cleaning method for 2D materials. By our ice transfer and ice cleaning methods, contamination-free 2D materials can be achieved, which improves that application potential of 2D materials in semiconductor industry.

Advantages

- Contamination-free

- Low cost (nearly zero), time-saving (15 min)

- Environmental friendly

Applications

- FET devices

- Photoelectronic devices

- Bio-implantable devices