Praise for robotic arm designed by City University students that could have wide applications in construction, medicine and other industries

- The self-learning arm, called Jarvis, was the stand-out exhibit at the university’s event showcasing new technology to industry figures

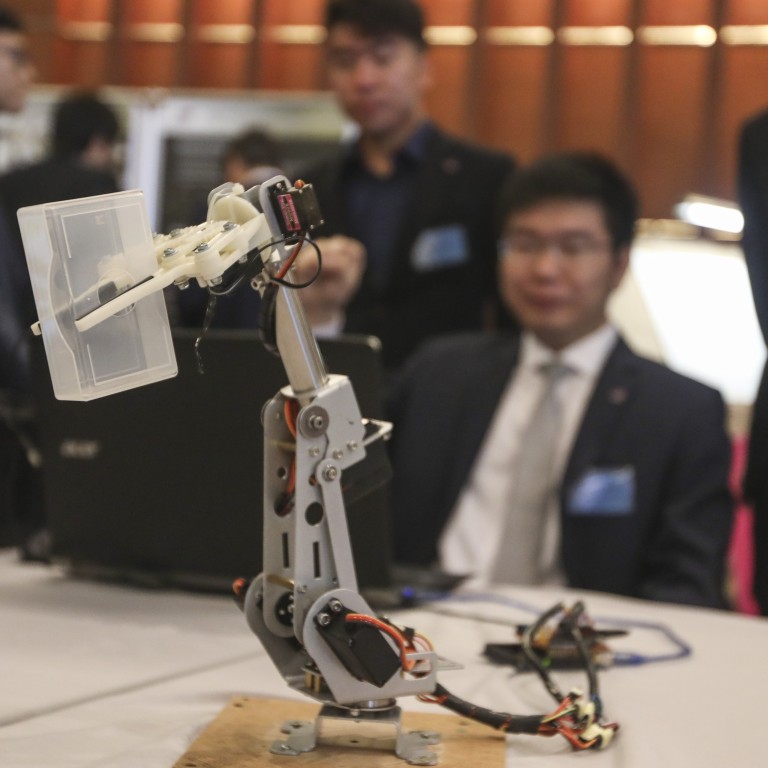

A self-learning robotic arm invented by a group of students at City University was the star attraction at an event showcasing new technology at the university on Tuesday, winning plaudits from a construction industry employer, who hopes it can be applied for industrial use.

The innovation was one of 40 inventions shown to hundreds of employers at the event.

The voice- and motion-activated digital tool called Jarvis, which is equipped with an array of grips, is trained by an AI manipulating system that uses big data to recognise patterns and characteristics and has a range of movements similar to those of a typical human being.

To allow the robot to complete tasks without needing to be programmed, five designers from City U’s department of mechanical engineering inputted a number of images into the machine so it could derive generalisations.

“The arm has been able to identify apples and oranges and complete tasks like picking an apple out of a pile of oranges, or repetitive demands like putting a number of apples into a basket,” explained one of the researchers, Ho Cheuk-lung, a final-year mechatronics major.

“By putting your palm in front of the system’s camera, it can also be controlled manually and remotely to perform tasks mirroring your movements, which could become useful in advanced manufacturing,” said another designer, She Ka-chun.

Ho and She, together with three other classmates, anticipated their invention would help with procedures requiring high precision, such as surgery or firefighting.

One director of a surveying company said the invention could be a great help in tackling a manpower crisis in the construction industry and in turn lower the overall costs of construction projects.

“Currently, we are seeing a labour shortage, with many skilled construction workers coming to retirement age and not a lot of young blood wanting to join the industry. That is why I believe robotic systems can really help address the pressing concern,” Anderson Chan Man-hong, director of surveying company, Rider Levett Bucknall Limited said.

At Hong Kong hackathon hackUST, 24 hours to build a winning game or app that solves a social problem

“The arm these students designed can increase the productivity of tasks like coating, wiring, and bricklaying due to the high level of precision and quality; eventually the costs of such projects could drop because we will not have to hire so many workers,” he added.

Around 600 people attended the event, including 350 employers from more than 200 companies across a range of industries, plus 250 faculty members and students.

Speaking at the event, the university’s president also underlined to students the importance of using their knowledge to help the community.

“Data science can help predict what will happen in the future and can also analyse the past to resolve complicated issues in society. We are not just asking our students to study technology but also to create things based on their knowledge,” said Professor Way Kuo.