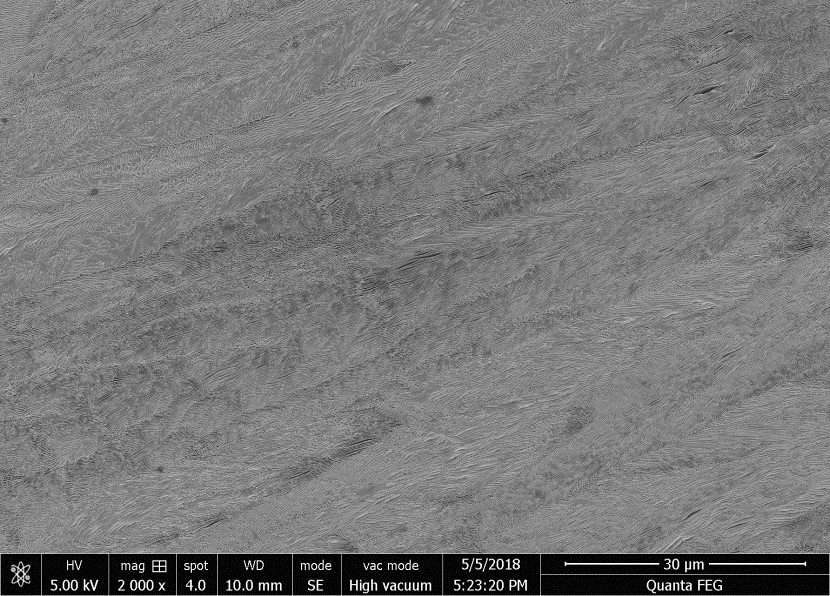

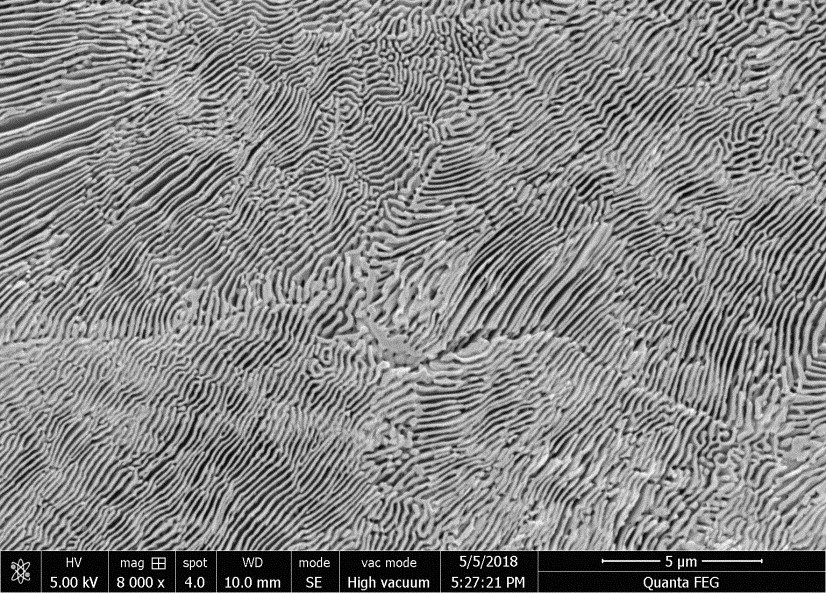

Figure 1. Scanning electron microscopy image of an as-cast high entropy alloy as prepared in accordance with one embodiment, magnification: 1000X (left) and 8000X (right).

Opportunity

Eutectic high entropy alloys (EHEAs) contain multiphases with nanometer length scale. Compared with conventional eutectic alloys, EHEAs have multiple elements in each phase whose synergistic effect leads EHEAs to optimal mechanical and functional properties. The inventors fabricated 3-dimensional (3D) porous structures that show great potential as a catalyst for hydrogen evolution reaction (HER) due to their tremendous specific surface area and multicomponent effects in ligaments. Given their good mechanical properties, hydrophobic properties, and catalytic properties for HER, as well as their resistance to corrosion, these 3D porous structures are competitive candidates for both functional and structural applications.

Technology

The inventors used a Co-Cr-Fe-Ni-Nb EHEA as a template to fabricate the 3D porous structures and chose various processing conditions (e.g., casting, melt spinning, heat treatment, etching) with specific series and conditions to process a variety of 3D porous structures. Each porous-structured sample has homogeneously distributed microstructures, and the size of the sample can be as large as 100 mm by 10 mm by 1 mm, which is larger than similar structures fabricated by other techniques. The length scale of the ligaments is tunable by controlling the processing conditions and covers a wide range, from several tens of nanometer to several microns. In addition, due to the tunable porous/ligament size, this kind of structure shows good hydrophobic properties—the contact angle of water droplet can be as large as 140 degrees, which is far beyond that of the bulk counterpart (~40 degrees). Furthermore, this kind of structure has strong and hard ligaments, but the total density is only around 4g/cm3, approaching the commercial lightweight TiAlV alloy. The hardness of the porous structure is xxx, which is a good candidate for structural materials and can be used to fabricate small, lightweight devices.

Advantages

- Controllable microstructures

- Easy and inexpensive procedures

- Large dimension of products

- Stiff porous structure

- Structures with multi functions

Applications

- Clean energy industry

- Surface engineering