Opportunity

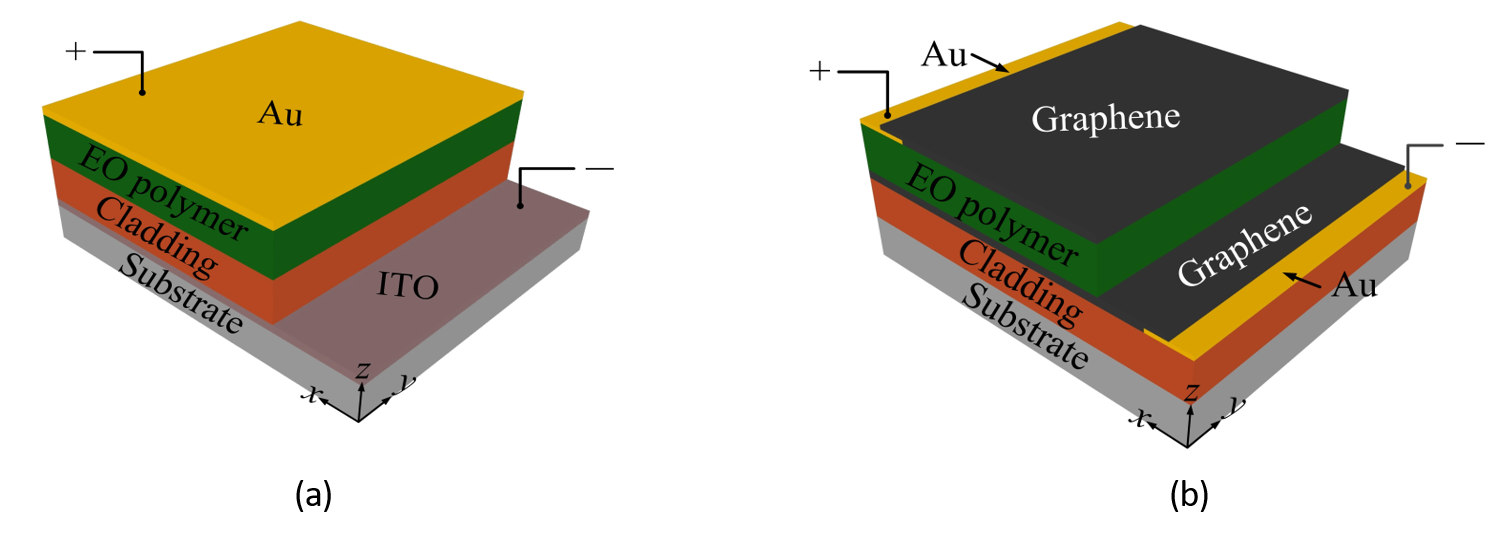

Electro-optic (EO) polymer materials can be utilized for encoding the optical signal with electric signal. To prepare the EO polymer film, an electric poling process is involved by applying electricity to force the molecular dipoles, i.e. positive and negative charges, to orient in a designated direction within the polymer film. Conventional methods to prepare the EO polymer film involving metal and indium tin oxide (ITO) electrodes are absorbing light and thus require thick enough buffer layer that would affect efficient poling of the EO polymer film. Therefore, improving the preparation of EO polymer films would be intriguing and impactful for the fabrication of photonic devices, such as electro-optic modulators, silicon-organic hybrid waveguides, optical electric-field sensors, new frequency generators, and all-optical switches.

Technology

In this invention, graphene electrodes are employed to lower the voltage for poling process, eliminate the use of unwanted buffer layer, and allow the use of inexpensive cladding material. The resulting EO polymer film demonstrates that the present poling process with graphene electrodes does not introduce significant additional optical loss to the EO polymer. Furthermore, graphene holds the advantages of excellent conductivity and low-loss at communication band, thereby the graphene material left behind after the electric poling process is beneficial for further processing of the EO polymer film. Accordingly, the use of graphene electrodes allows more flexible designs of electro-optic devices based on EO polymer films and can potentially simplify the fabrication of such devices.

Advantages

- Graphene electrodes are beneficial for further processing of EO polymer films

- Simplify the fabrication of electro-optic devices based on EO polymer films

- Low optical loss useful for flexible waveguide design

- Reducing manufacturing cost with lowered poling voltage and use of inexpensive cladding material

Applications

- Electro-optic modulators for high-speed optical fiber communication.

- High-performance organic EO materials for future ultrafast information processing

- Silicon-organic hybrid waveguides

- Optical electric-field sensors

- New frequency generation