Opportunity

Graphene is a single layer of carbon atoms tightly arranged in a two-dimensional hexagonal honeycomb lattice. Particularly, the unique structure of multi-layer graphene material with porous structure brings about desirable properties, including light, excellent conductivity of heat and electricity, and outstanding mechanical properties. These properties have drawn particular interest in wide-ranging applications such as gas separation, chemical sensing, hydrogen storage, and supercapacitors. These properties also stimuli interest in further development, for example, for use in sensors, detectors, transistors, advanced batteries, and many other non-electronic applications. However, usual large scale industrial manufacturing processes, like mechanical and chemical manipulations, for obtaining graphene related materials cannot be sufficiently controlled, and usually suffer from the issues of low efficiency, involving a number of reaction steps, time consuming, requiring high energy consumption, and high costs. There remains a pressing need to produce large amount of high-quality graphene and/or related materials meeting industrial requirements to furnish various applications.

Technology

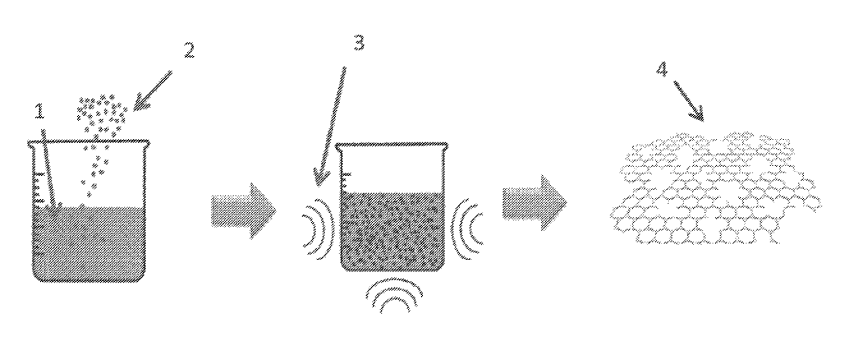

The present invention relates to a method of producing a nanoporous graphene material by a direct sonication assisted method, which comprises the first step of reacting carbide nanoparticles with acid assisted by sonication to accomplish the nanoporous graphene material in solvent, and the second step of purifying and washing the resulting graphene material. This method utilizes carbide which is composed of carbon and at least one metallic or semimetallic element. “Sonication” generally refers to the mild irradiation of a liquid sample with sound energy to facilitate the reaction. This method enables direct and simple large-scale synthesis with mild conditions in short time, meanwhile, does not involve toxic chemicals. Furthermore, the excellent electrical conductivity of the resulting porous graphene material is retained. The obtained nanoporous graphene material can be used in the production of various electronic articles.

Advantages

- Compared to the conventional methods, the present invention afforded nanoporous graphene material with excellent electrical conductivity, due to the direct chemical method.

- The nanoporous graphene material synthesized by this method is template-free and does not attach to any substrate, so the porous graphene material could be directly used for next process.

- This method enables large-scale production in short time.

- This method enables room temperature and atmospheric pressure operation, therefore, the requirements of equipment are reduced and all the processes are easy to control.

- Meanwhile the chemicals used are non-toxic, and the whole process does not cause harm to the environment.

Applications

- Gas separation, chemical sensing, hydrogen storage, semiconductors

- Sensors, transistors, detectors, advanced batteries

- Electrically conductive plastics, reinforced composite materials

- Production of electronic articles such as electronic circuits and energy-storage devices